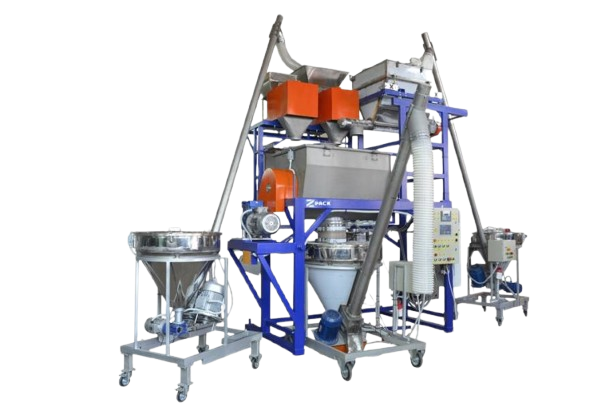

Complex for automatic weighing, dosing and mixing of bulk components – allows you to automatically and efficiently dose and mix any bulk components in the required proportions.

The components are loaded into the dosing bin using conveyors according to the principle – „a conveyor for each ingredient”. The loaders are equipped with frequency controllers, which allow you to smoothly add the component to a specified weight. The dosing bin is hermetically connected to the conveyors and mixer using flexible hoses.

Description of work.

The line is automated and controlled by a controller.

The operator selects or sets the mixture recipe on the control panel and then loads the necessary components into the conveyor bins for large and medium doses. For small doses, the operator pre-weighs the components in the required proportions, based on the total loading volume of all small doses, and loads them into the pre-mixer for micro components.

After loading all the components, the complex operates automatically, the operator only pours the components into the conveyor bins. The components are fed into the batchers, weighed, mixed and unloaded automatically. The hoppers of the loaders for feeding large, medium and small doses are equipped with level sensors that inform the operator about the presence of the product for mixing and give a command for dosing or unloading from the mixers. Also, the screw loaders are equipped with frequency converters that organize a smooth addition of the product to the batcher, ensuring the accuracy of weighing. All the hoppers of the screw loaders are equipped with frame mixers that prevent the product from caking.

The batchers are installed on load cells that weigh the components in the batcher hoppers and control the product feed by screw conveyors.

The mixing cycle time and automatic unloading from the mixer are set by the operator on the control panel. The finished mixture from the belt mixer is automatically unloaded into the receiving hopper of the feed conveyor for feeding to the next technological operation or into the storage hopper of the finished mixture with subsequent dosing. After unloading the finished mixture from the mixer, the unloading valve closes automatically and the components are dosed for the next cycle.

Features.

The bulk component dosing and mixing complex allows automatic dosing and subsequent mixing of various bulk components, while significantly reducing the human labor component in the technological process.