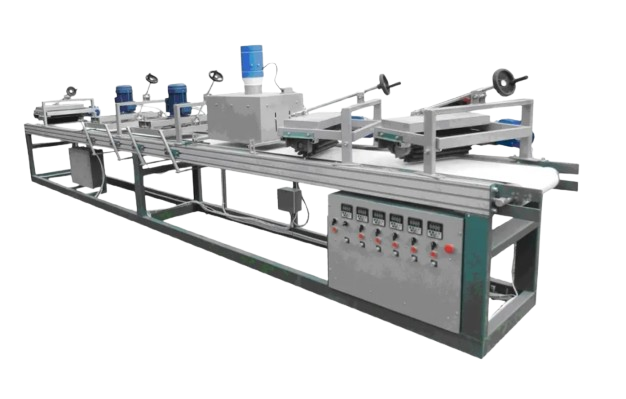

Grinding machine RSP-5UV

Functionally, it consists of a base with a conveyor feed of the workpiece, 2 height-adjustable units with disk brushes or PADs and 3 units with cylindrical brushes (at the entrance and exit of the machine).

The feed speed of the workpiece is smoothly regulated using a frequency controller (2-15 m / min). The rotation speed of the working tool is also regulated by frequency converters.

RSP-5UV grinding machine is high-tech equipment designed for grinding various materials, including paints, coatings, varnishes, as well as other liquid and pasty substances. It is used in the paint and varnish, chemical, pharmaceutical and other industries to obtain uniform and high-quality mixtures with specified characteristics.

Specifications.

| Motor power | 1 kW |

| Dimensions of the processed material | |

|---|---|

| Maximum material width | 400 mm |

| Maximum material thickness | 150 mm |

| Maximum material length | 9000 mm |

| General parameters | |

| Weight | 500 kg |

| Width | 450 mm |

| Height | 750 mm |

| User specifications | |

| Manufacturer | Z-machine |

| Length | 6000 |

| Number of motors | 5 |

Main characteristics of the RSP-5UV machine:

- Operating principle: The grinding machine operates on the basis of mechanical energy transmitted through the shaft and the grinding system, which allows for effective mixing and grinding of particles in the material. The process is carried out using grinding rollers or discs, which ensures uniform distribution of abrasive particles over a liquid or paste base.

- Special ultraviolet treatment (UV): The machine is equipped with an ultraviolet treatment system, which helps improve the quality of the coating and accelerate the polymerization process. UV lamps activate chemical reactions, which increases the strength and wear resistance of the mixtures.

- High productivity: The RSP-5UV model has a high productivity and can process large volumes of material in a short time, making it suitable for mass production.

- Multifunctionality: This machine can be used to grind and mix various types of mixtures, including paints, pastes, chemical compounds and pharmaceuticals. It is ideal for processing materials with different viscosity and structure.

- Parameter adjustment: The machine provides the ability to adjust the speed of rotation of the shafts, pressure on the material, temperature and intensity of UV treatment, which allows you to adapt the process to different materials and production requirements.

- Process automation: The grinding machine is equipped with modern control systems, which allows you to automate the grinding process and control the operating parameters in real time. This reduces the need for manual labor and increases the accuracy of processing.

- Design and materials: The machine has a robust and durable design made of high-quality materials that are resistant to wear and chemical influences, which ensures a long service life of the device.

Advantages of the RSP-5UV grinding machine:

- High quality processing:

Thanks to ultraviolet treatment and precise adjustment of operating parameters, the machine ensures excellent quality of the final product, improving the physical and chemical properties of the mixtures. - Increased production speed:

Ultraviolet treatment accelerates the polymerization process, which helps to increase productivity and reduce the time for each cycle. - Saving materials:

The machine allows for more efficient use of materials, reducing the amount of waste and losses due to precise dosing and uniform distribution of components. - Energy efficiency:

The use of ultraviolet radiation and a modern control mechanism can significantly reduce energy costs for the processing process. - Versatility:

RSP-5UV is suitable for various industries, such as the production of paints and varnishes, cosmetics, pharmaceuticals, chemical industry, providing high-quality results with various types of mixtures. - Low operating costs:

Ease of maintenance and durability of the machine reduce its operating costs, which makes it a profitable investment for companies engaged in the production and processing of mixtures.

Application of the RSP-5UV grinding machine:

- Paint and varnish industry:

It is used to create paints, coatings, enamels, varnishes, and other coatings that require high quality and uniform distribution of abrasive particles. - Pharmaceutical industry:

It is used to process pastes and creams that must have a stable and uniform texture. - Cosmetic industry:

It is used to grind and mix components from which creams, ointments, and other cosmetic products are made. - Chemical industry:

It is used to create various chemical compounds, including pastes and liquids that require thorough and uniform processing.