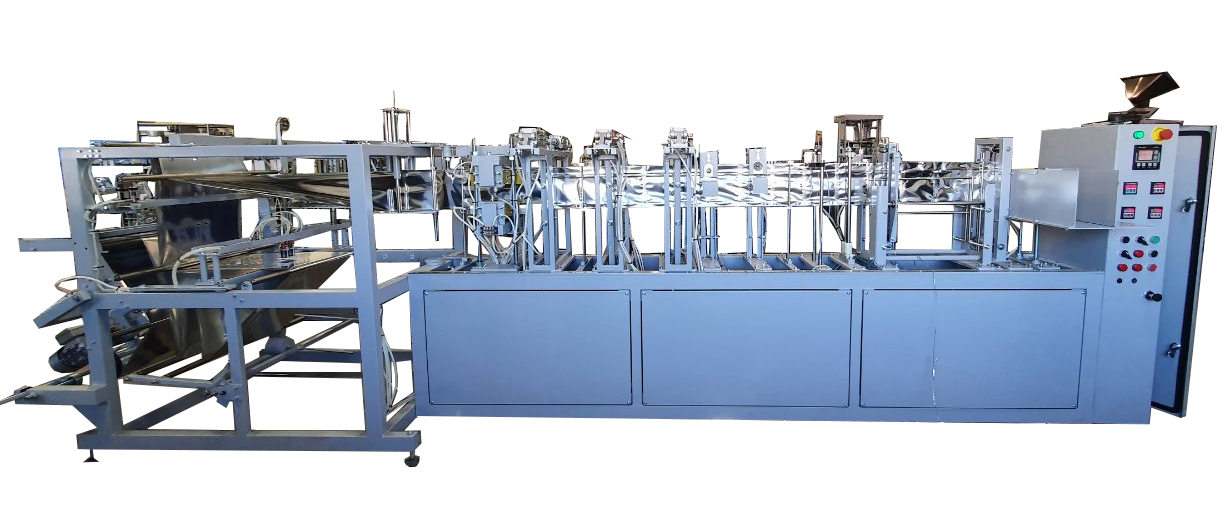

The bag-forming machine is designed to organize a continuous cycle of doy-pack packaging production. Single-layer and multi-layer packaging films (except for single-layer polyethylene) are used to produce the bag.

The automatic line consists of a packaging former and a device for sealing and storing finished doy-pack bags.

The bag-making machine allows you to form and produce doy-pack bags of various modifications, with a capacity of up to 1800 packages/hour.

Characteristics.

| Power supply, V/Hz | 380/50 |

| Electricity consumption, kW/hour | 2,5 |

| Pneumatic supply*, atm./l.min. | 6/250 |

| L/W/H (not more than), mm | 4900/1400/1500 |

| Weight (not more than), kg | 450 |

| Film roll width/diameter (max), mm | 720/300 |

| Productivity, pack.hour | 1800 |

| Package L/W (min.), mm | 90/150 |

| Package L/W (max), mm | 300/250 |

* To ensure the operation of the pneumatic drives of this equipment, a compressor is required (not included).

**Productivity depends on the width of the package and the properties of the packaging material.

Description of work.

The polymer film is unwound from the roll using an electric drive controlled by the controller. Then, via a system of rollers with a tensioner, the film is fed to the unit for folding the package (package) and forming the bottom (flat or smile), with preliminary perforation, for guaranteed sealing of the seams.

After forming the bottom of the package, the film enters the unit for sealing the bottom of the package and sealing the ZIP-lock (not included in the standard package), then to the unit for sealing the vertical seams of the formed doy-pack bag. After sealing the seams of the package, the controller sends a signal to pull the formed bags into the accumulator. Simultaneously, with the sealing of the seams of the doy-pack bag, the mechanism for separating the packages is triggered by cutting with pneumatic scissors.

The sealing unit of the bag-forming machine operates on the principle of constant heating (sealing with the “euro-bag” type). Includes vertically located welding pads (jaws), placed one after another, observing the step multiplicity, depending on the width of the doypack packaging being manufactured. In the case of a ZIP lock, the sealing unit includes a horizontal welding pad.

The bag-making machine is controlled by a controller that monitors the presence, jamming or tearing of the film, and also monitors other operating modes and emergency situations: air pressure, stop by counter, etc.

Peculiarities.

Doy-pack is a special type of flexible packaging, which is a polymer bag with a bottom, which allows the package, when filled, to be stable in a reticulated position.

The automatic bag-making machine is designed to produce doy-pack bags used for packaging bulk and liquid products, including: tea, granulated, freeze-dried, ground and grain coffee, mayonnaise, ketchup, condensed milk, etc.

This bag-making equipment is designed to operate on the floor, with adjustable supports. The machine is available in one modification, model ADP-1, with the ability to install additional units, indicated in the “equipment” section.

Equipment.

Standart equipment:

Film unwinding unit;

Packaging formation unit;

Automatic bag pulling unit;

Packaging sealing unit;

Packaging accumulator;

Electronic control unit;

Packaging formation unit by photo mark;

Light system for indicating work processes.

Additional equipment:

ZIP-lock welding unit;

Package cutting unit;

Table for gluing film strips;

Dater (6 symbols on the package seam in the format – day, month, year (“XX XX XX”));

Thermal printer (from 6 symbols, at any point on the package);

Compressor.

Equipment:

Electric drives – STM (Italy);

Used – MiKra (Ukraine);

Frequency converters – INVT, HYUNDAI (Korea);

Bearings – CX (Poland).

Possibilities: 1800 packs/min.

Type of packaging: doy-pack bag.

Products: any except PVC, POF, PE.