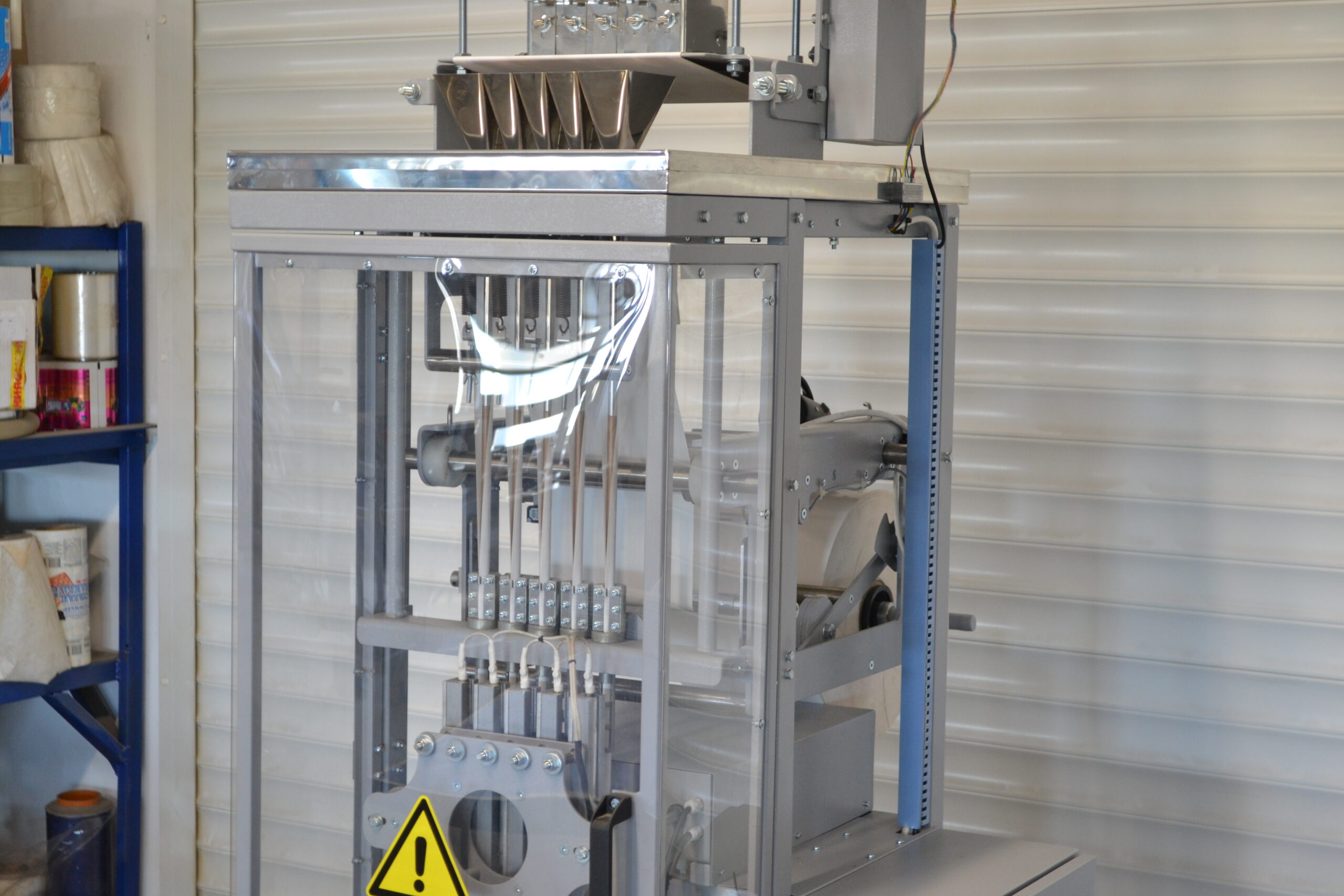

The vertical packaging machine with a volumetric belt dispenser, model AF-120-OM(L)1-5, is used for the automatic process of portion packaging and packing in a 3-seam package, in the form of a “stick”, sugar, salt, pepper, instant coffee and other products from 2 to 20 cm3. Any multilayer film, laminated paper in a solid roll (regardless of the number of streams) can be used as packaging material.

Characteristics.

| Power supply, V/Hz | 220 / 50 |

| Electricity consumption, kW/hour | 1,5 |

| Pneumatic supply**, atm./l.min. | 6/200 |

| Length/Width/Height (not more than), mm | 900/ 1100/ 2300 |

| Weight (not more than), kg | 180 |

| Film roll width/diameter (max), mm | 250 / 300 |

| Productivity (max.)*, packs/hour | 2400-12000 |

| Volume of storage bin, l | 20 |

| Dosage range, cm3 | 2-20 |

| L/W of package (max), mm | 200 / 17-35 |

* The equipment performance depends on the dose volume, the properties of the packaged product, the properties of the packaging material and the length of the package.

** To ensure the operation of the pneumatic drives of the packaging machine, a compressor is required.

Description of work.

The product being dosed, due to good adhesion to the dosing belt, is pulled out from the neck of the feeding hopper (through adjustable flaps in the hopper) and moves the product to the loading funnels, through which it is poured into the tubes. The product enters the formed package (stick) through the tubes and fills it to a specified level.

After filling the package to a specified level, the ECU sends a signal to the stepper motor to start the drive of the transport belt, which leads to the launch of a new product packaging cycle.

The seam sealing unit operates on the principle of constant heating. The sealed type of seam “euro-bag” is the upper seam of the already filled stick package. The side and lower seam seal the stick package for the next batch of products. The moment of sealing the stick package, the heating elements (jaws) located horizontally, as well as the sealing unit (carriage) are shifted by a specified length of the package to the lower part of the machine. The jaws remain compressed during the downward movement, which allows the packaging material to be pulled. The roll is unwound and the packaging material is rolled up through the stick packaging former (collar) into a sleeve around the guide tube.

When the product being packaged and packed in a stick package reaches the bottom of the machine, it is separated using a serrated (straight) knife by cutting the packaging material. Spilling through the tube, the product being packaged fills the formed package (stick). The cut package falls onto the floor, into a special container (box) or onto a discharge conveyor.

Peculiarities.

The AF-120-OM(L)1-5 filling and packaging machine is an improved descendant of the AF-120-OM model. The new model is distinguished by the versatility of the volumetric belt dispenser (no transition troughs – no product sticking), which allows it to be used for separating into portions (dosing) almost any type of product that is used for packaging in a stick bag. The design has changed dramatically. It is now possible to move the equipment using a stacker without using a pallet. The number of pneumatic drives has decreased, which has simplified equipment maintenance, and the costs of purchasing cheaper compressor equipment have also decreased. The controls have received additional capabilities to track machine stops (product presence sensor in the hopper, product jamming, stop when opening the protective casing). The new version of the equipment is available in 5 modifications. The difference between them is the difference in the number of packaging tracks (streams) used, as well as productivity. So, in the AF-120-OM(L)1 model there is 1 stream, with a capacity of up to 30 packages/minute. The AF-120-OM(L)5 model has 5 streams, with a capacity of up to 150 packages/minute.

Possibilities: 2400-12000 packs/hour.

Type of packaging: stick pack.

Products: bulk products.