This filling and packaging machine is designed to provide a continuous packaging cycle, volumetric dosing of bulk products (fuel granules, pellets, animal feed, sand, crushed stone, salt, fertilizer) and their packaging in polyethylene (PE) or multilayer films.

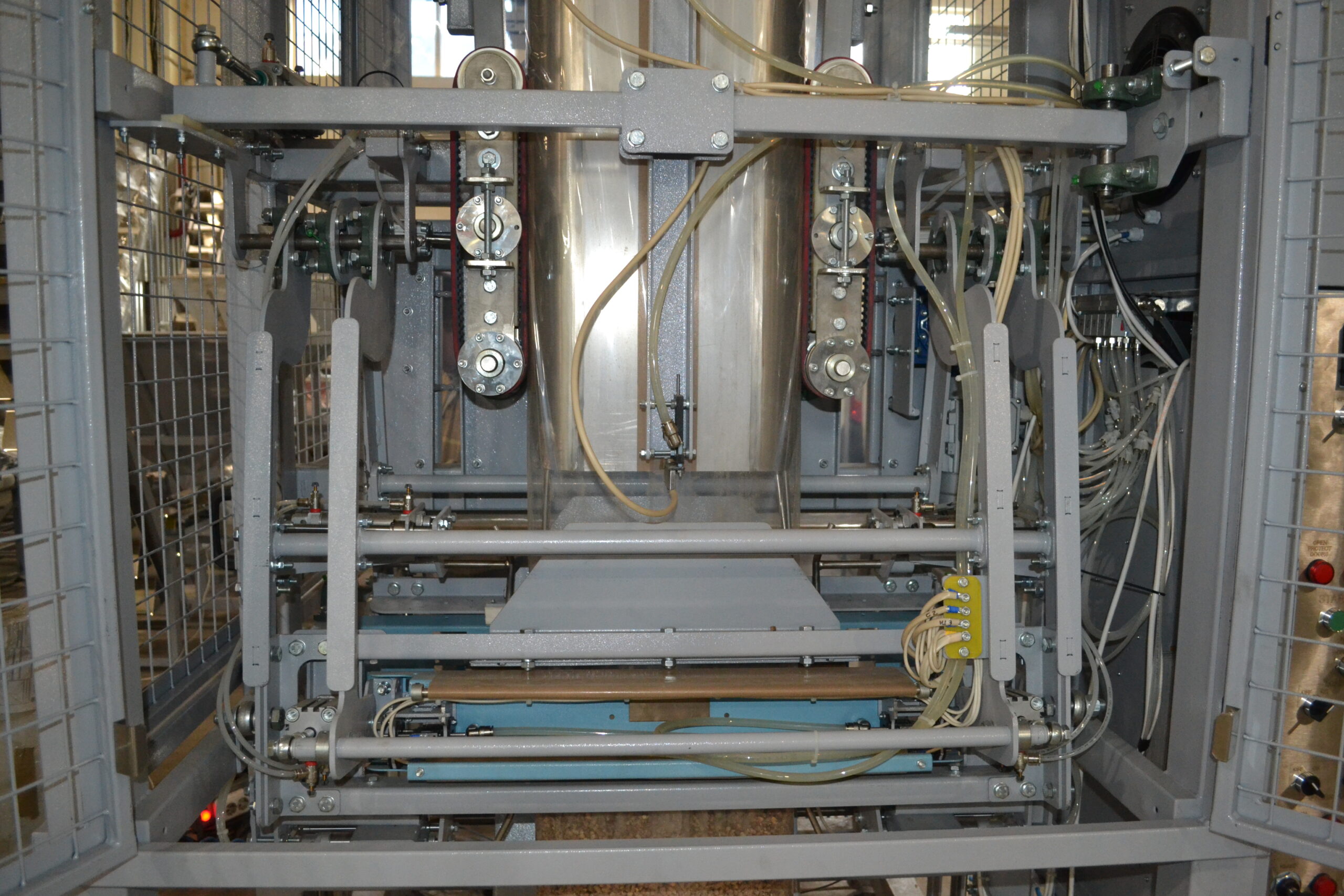

The equipment consists of a vertical packaging machine and a volumetric dispenser with a belt feeder.

The equipment allows for dosing (packaging) of bulk products from 2 to 50 liters, and their packaging in large packages (bags).

Characteristics.

| Power supply, V/Hz | 380/50 |

| Electricity consumption, kW/hour | 3,5 |

| Pneumatic supply**, atm./l.min. | 6/500 |

| Length/Width/Height (not more than), mm | 2900/1800/4600 |

| Weight (not more than), kg | 950 |

| Film roll width/diameter (max), mm | 1050/500 |

| Productivity (kinetic)*, packs/hour | 500 |

| L/W of package (max), mm | 700/500 |

| Dosage range, cm3 | 2 000 – 50 000 |

| Volume of storage bin, l | 100 |

* Productivity depends on the weight of the dose, the length of the package, and the properties of the packaging material.

** To ensure the operation of the pneumatic drives of this packaging machine, a “compressor” is required (supplied separately).

Description of work.

The packaged product is poured through the hopper neck onto the feeder *, with the help of which it is fed into the funnel of the tube of the sleeve-forming device.

* The feeder can be made in the form of a vibrating tray or a polyurethane conveyor belt (the belt is more suitable for fragile, hard-to-flow products; in other cases, a vibrating tray is used). The operation of the feeder is controlled by a control unit, which, by supplying power to an electric motor or an electromagnet, makes the conveyor belt rotate or creates vibrations in the vibrating tray, thereby moving the product from the hopper neck to the funnel of the tube.

On the tube, the packaging material is rolled up into a tube (sleeve) with a sealed back seam and bottom. In this case, the bottom seam is clamped in the horizontal clamps of the sealing unit.

Spilling through the funnel along the tube, the product fills the bottom of the tube (package) and the tube itself. Considering the weight of the dose and the pressure created on the bottom seam, the horizontal clamps remain compressed until the dose is dispensed. This eliminates pressure on the seam and the possibility of its rupture if the packaging material has not cooled down from welding.

A capacitive sensor is located inside the tube, which reacts to the filling of the tube. As soon as the product, filling the tube, approaches the capacitive sensor at a set distance, the latter sends a signal to the control unit.

The control unit stops the feeder (stops the power supply), releases the clamps of the soldering unit and turns on the feeding of the packaging material. Considering that the packaging is welded directly on the web of the packaging material, when it is fed, the roll is unwound and the packaging material is rolled up, by means of a collar, into a sleeve around the tube. The feeding is carried out using an electric motor and belts to the length set by the operator.

After the end of the feed, the control unit compresses the clamps again, fixing the packaging material, and also compresses the welded elements located on the clamps and presses the vertical welded element to the tube, starting the process of welding the seams. At the same time, the control unit activates the dispenser feeder, filling the package. The soldering unit operates on the principle of constant heating, i.e. welded elements are pressed to the packaging material for a specified time (set interval), on which the set temperature is maintained. After the specified welding time has elapsed, the welded elements are released, and the horizontal clamps continue to remain compressed. This is necessary for cooling the packaging material and forming strong seams, which is especially important for polyethylene films *, the seams of which retain plasticity for a long time after welding and can be torn even by minor efforts. To speed up the cooling process, immediately after the welded elements are released, the control unit supplies compressed air to the nozzles located on the soldering unit and forcibly cools the formed seams (the blowing time is adjusted by the operator).

* The equipment allows the use of any polymer films as packaging material, but, given the dose sizes and the optimal cost of packaging, the most appropriate is to use polyethylene films.

The soldering unit simultaneously seals the top seam of the filled package, the bottom and back seams of the next package in one go. At the same time, at the moment of welding, the filled package is separated by cutting the packaging material with a hot “string” located on the protrusion of the horizontal welded element.

After the welding process is complete and the formed seams are cooled, the control unit releases the horizontal clamps and again turns on the packaging material feed, feeding the next filled package to the soldering unit. At the same time, the package, already sealed and cut off by the “string”, is lowered onto the discharge conveyor.

Peculiarities.

This packaging machine is ideal for packaging products that are convenient to sell in large packages (bags). Such products can be: sand, fuel granules, pellets, grain, salt, sugar, washing powder, pebbles, crushed stone, soil (not wet), compound feed, fillers for animals.

The packaging machine is not suitable for packaging highly dusty products. It should be taken into account that due to the use of a volumetric dispenser, the model is not universal and has restrictions on changing the product being packaged.

This device requires floor placement and has restrictions on the width of the film used and the height of the formed package, specified in the technical specifications.

Equipment.

Standart equipment:

Volumetric dispenser with belt or vibration feeder and storage bin;

Former of 3-seam packaging “pillow” – collar (up to 1050 mm);

Automatic belt feed system for packaging material according to “photo mark”;

Sealing unit for longitudinal and transverse seams of packaging, with simultaneous air cooling;

Electronic control unit with light indication and monitoring of emergency situations.

Additional equipment:

Loading and discharging conveyor;

Tube with collar (for changing the film width);

Unit for forming a “stand-up package”;

Encoder (for pulling the film along the length of the package);

Thermal printer (from 6 characters, at any point in the package);

Unit for forming a handle on the package (“3 fingers”);

Protective cover;

Compressor.

Equipment:

Electric drives – STM (Italy);

Pneumatic drives – CAMOZZI (Italy);

Used – Libra, MiKra (Ukraine);

Frequency converters – INVT, HYUNDAI (Korea);

Product contact units – 304 steel.

Possibilities: 500 packs/hour.

Type of packaging: bag (pillow/standing).

Products: bulk products.