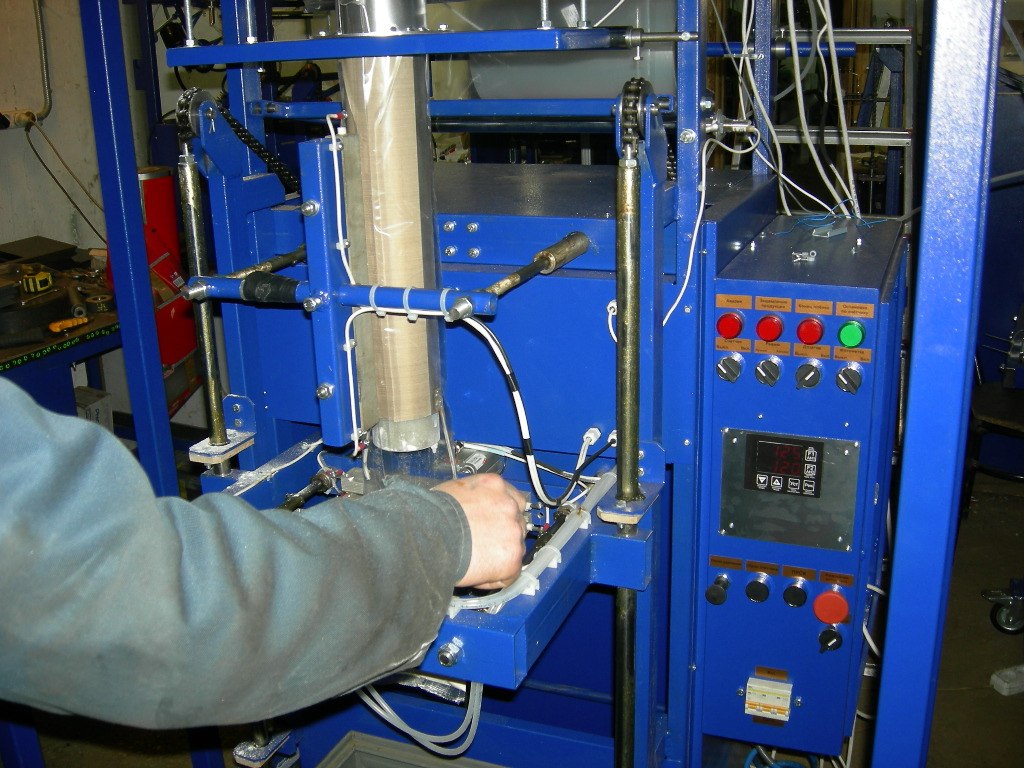

The packaging machine is designed to organize a continuous packaging cycle, using a volumetric dosing method, of dust-forming bulk products (flour, dry milk, starch) and their packaging in polymer films (polypropylene, duplex, triplex) with the formation of packages (pillow or standing). The automation completely controls the process of packaging and packing of products, so human participation is reduced to a minimum.

The equipment consists of a pneumatic packaging machine and a volumetric screw dispenser.

The packaging machine is the most budget equipment for packaging dust-forming products (among similar models of equipment), and also has the ability to change the size and characteristics of packaging materials.

Characteristics.

| Power supply, V/Hz | 380/50 |

| Electricity consumption, kW/hour | 2 |

| Pneumatic supply**, atm./l.min. | 6/250 |

| Length/Width/Height (not more than), mm | 1200/1700/3200 |

| Weight (not more than), kg | 420 |

| Film roll width/diameter (max), mm | 380/300 |

| Productivity (max.)*, packs/hour | 1500 |

| Volume of storage bin, l | 60 |

| Dosage range, cm3 | 50–1000 |

| L/W of package (max), mm | 300/180 |

* Productivity depends on the dose volume, packaging length, and properties of the packaging material.

** To ensure the functioning of the pneumatic drives of this packaging machine, a “compressor” (supplied separately) is required.

Description of work.

The packaged product is poured down the inclined walls to the hopper neck, connected to the tube of the sleeve-forming device. A vertically positioned auger passes through the neck and the tube, the upper part of which is fixed in the electric drive. Spilling through the neck, the product fills the cavities between the screw surface of the auger and the inner surface of the tube. To prevent it from spilling, a valve is provided in the lower part of the tube.

When power is supplied from the CT201 meter, located in the control unit of the packaging machine, the electric drive begins to rotate the auger, thereby moving the product from the hopper down the tube. The rotation speed of the auger is determined by the values set on the frequency converter. In addition, the electric drive activates the “stirrers” in the hopper, which mix the product, preventing bridging and better pouring of the product to the hopper neck.

During the rotation of the screw, the valve in the lower part of the tube opens and the product moved by the screw is poured into the packaging film folded on the tube like a sleeve with a sealed back seam and bottom (packaging blank). After reaching the number of pulses set on the counter “CT201”, the power supply to the electric drive is stopped, the screw stops and the valve on the tube closes, cutting off the delivery of a dose of product to the packaging blank. At the same time, the counter “CT201” sends a pulse to the microcontroller that controls the operation of the packaging machine.

Having received the pulse, the microcontroller uses pneumatic drives to activate the soldering unit. The soldering unit uses the principle of constant heating and in one step simultaneously seals the top seam of the filled package, the bottom and side seams of the next package with the “euro-roller” type of seam.

In this case, during the welding process, the horizontal jaws of the soldering unit (carriage) are shifted downwards by the set length of the package. Since the jaws move downwards without releasing, they pull the packaging film along with them. The roll is unwound and the film is rolled up through the collar into a sleeve around the tube.

When the carriage reaches the bottom point, the filled package is separated by cutting the film with a mechanical serrated knife. At the same time, the microcontroller of the packaging machine sends a pulse to the counter “CT201”, which supplies power to the dispenser’s electric drive, filling the next package. At the same time, the microcontroller releases the horizontal jaws and moves them upward to seal the next package. The cut package falls onto the floor, into a special container (box) or onto a discharge conveyor. Additionally, the microcontroller monitors the moments of emptying the dispenser hopper, the end of the roll of packaging material and other emergency situations.

Peculiarities.

The filling and packaging machine is optimal for packing dust-forming bulk products such as flour, dry milk, starch, cement, chalk. The machine allows you to arbitrarily change the size of the dose and the packaged product, but it should be borne in mind that this filling machine uses a volumetric dosing method, measuring the dosed product not by weight, but by the number of revolutions of the auger. Therefore, when changing the dosed product, it is necessary to take into account its density, since with the same number of revolutions for different products, the weight of the portions may differ.

The filling and packaging machine has significant dimensions and weight and requires floor placement. There are also restrictions on the width of the film used and the height of the formed package, specified in the technical specifications. It is possible to manufacture a filling and packaging machine of increased dimensions – the maximum film width will be up to 500 mm, and the height of the package up to 400 mm.

Equipment.

Standard equipment:

Volumetric screw dispenser with a storage bin with agitator;

Former of 3-seam packaging “pillow” – collar (up to 380 mm);

System of automatic carriage feeding of packaging material along the length and along the “photo mark”;

Unit for sealing longitudinal and transverse seams of the packaging with “euro-rollers”;

Unit for putting the date on the seam of the packaging (day, month, year “XX XX XX”);

Electronic control unit with light indication and monitoring of emergency situations.

Additional equipment:

Tube with collar (for changing the film width);

Unit for forming a “stand-up package”;

Thermal printer (from 6 characters, at any point of the package);

Device for applying a punch to the seam (“Euro loop”, “Euro punch”);

Protective cover;

Compressor.

Equipment:

Electric drives – STM (Italy);

Pneumatic drives – CAMOZZI (Italy);

Used – Libra, MiKra (Ukraine);

Frequency converters – INVT, HYUNDAI (Korea);

Product contact units – 304 steel.

Possibilities: 1500 packs/hour.

Type of packaging: package (pillow/standing).

Products: bulk products.